The Rise of Self-Healing Asphalt: What It Means for Pothole-Free Roads in the Midlands

Potholes. They’re the bane of every motorist, a constant headache for councils, and an ongoing challenge for surfacing professionals across the Midlands and beyond. But what if our roads could actually fix themselves? Thanks to pioneering advances in self-healing asphalt, the dream of creating pothole-free roads in the Midlands is moving from science fiction to reality.

What Is Self-Healing Asphalt?

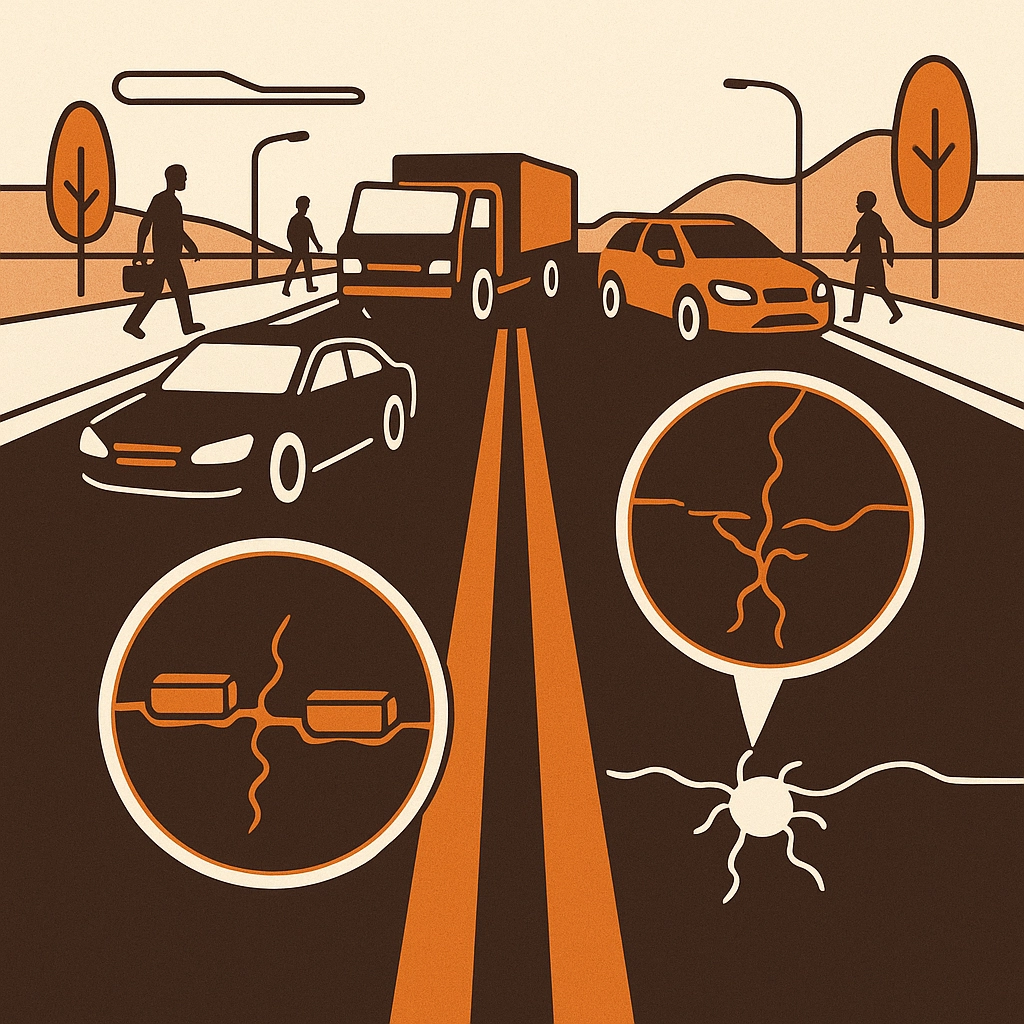

Self-healing asphalt is an innovative pavement material designed to fix its own minor cracks and damages—before they grow into costly, hazardous potholes. Unlike conventional asphalt, which requires regular intervention to repair damage from traffic and weather, self-healing asphalt can repair micro-damage autonomously.

Traditional asphalt roads typically age through a cycle of repetitive stress and environmental exposure. Over time, tiny cracks begin to form. Water seeps in, freezes, and expands, turning hairline fractures into outright potholes. Regular maintenance is expensive, disruptive, and – let’s face it – not always timely. The Midlands alone faces millions in annual repair bills and road closures due to this never-ending battle.

Enter self-healing technology: a blend of smart materials, clever chemistry, and, increasingly, artificial intelligence. These new asphalt mixtures can respond to early signs of damage, offering a proactive approach to road maintenance.

How Does Self-Healing Asphalt Work?

The magic lies in both the materials used and the science behind the process. Most self-healing asphalts leverage the viscoelastic properties of bitumen, which is the sticky, tar-like binder in standard asphalt. This natural property allows bitumen to partially ‘flow’ and fill cracks at a microscopic level, especially when conditions are right—like warm temperatures or after targeted heating.

However, the latest self-healing asphalts go far beyond this basic mechanism:

-

Induction Heating: Tiny steel fibres (like steel wool) are mixed into the asphalt. When a special electromagnetic field is applied over the surface, these fibres heat up, softening the surrounding bitumen. Cracks fill in, all without digging or patching. This technique is already seeing road trials in the Netherlands and is gaining traction across Europe.

-

Rejuvenator Microcapsules: These are miniature capsules embedded throughout the asphalt, filled with rejuvenating oils. When the road cracks, the capsules break open—releasing the oil, which travels into the crack and helps restore the bitumen's flexibility and adherence.

-

Biomass-Based Spores: In the UK, researchers from Swansea University and King’s College London have developed spores (essentially microscopic pods) from plant waste. These spores are preloaded with recycled oils. As micro-cracks develop, the spores rupture and release the oils, proactively healing the damage.

-

Bacteria-Based Solutions: Some researchers are experimenting with bacteria that precipitate calcite crystals, potentially sealing cracks from within the material.

Each of these methods targets the core of the pothole problem: small cracks before they become large ones. By stopping damage early, major repairs can either be drastically reduced or made unnecessary.

UK Research: Smart Roads and Greener Futures

The UK is positioning itself as a leader in self-healing asphalt development, driven by concerns over spiraling road repair costs and increasing environmental awareness. According to recent collaborations led by Swansea University and King’s College London, the Midlands stands to gain significantly from these new technologies.

Instead of relying on conventional, resource-intensive materials, the UK team’s approach uses biomass waste that would otherwise end up in landfill. Using artificial intelligence, they’re modelling the way organic materials interact under strain, optimising self-healing capacity while boosting sustainability credentials.

Why does this matter? The adoption of greener materials throughout the supply chain reduces CO₂ emissions and landfill waste—a win for the environment as well as taxpayers.

Pothole Prevention: What Could It Mean for the Midlands?

Crucially, self-healing asphalt addresses the pothole problem at its source. By actively repairing early-stage damage—something traditional asphalt simply can't do on its own—these surfaces help roads last longer, with safer, smoother journeys for everyone.

Some notable benefits:

-

Fewer Emergency Repairs: Self-healing asphalts can double the surface life of roads, according to Dutch trials. This translates to less need for disruptive and costly patch-ups.

-

Budget Relief for Local Councils: The Midlands has an extensive road network with frequent freeze-thaw cycles and heavy traffic. The ability to stretch maintenance cycles can save millions in public funds.

-

Reduced Carbon Footprint: Enhanced durability means less frequent resurfacing, lower raw material consumption, and fewer emissions from maintenance works.

-

Happier Drivers and Local Businesses: Fewer roadworks and smoother roads mean less frustration and a better image for the entire region.

Want to know more about our approach to innovative, sustainable surfacing? Explore our commercial surfacing services, or contact J.C. Surfacing Ltd for tailored advice!

Looking Ahead: The Road to Adoption

While self-healing asphalt is still being trialed—often on test sections rather than entire highways—the direction of travel is clear. As material costs fall and research progresses, it’s likely that we’ll see more Midlands councils and commercial developers considering these resilient materials for high-traffic and high-value locations.

Widespread adoption will require a shift not just in materials, but in mindset. Instead of viewing roads as disposable assets, self-healing asphalt allows for a whole-life approach—install once, then maintain infrequently through non-invasive techniques such as induction heating.

Of course, no technology is a silver bullet. Quick fixes for legacy roadbeds may still have their place, but the next generation of roads—motorways, commercial yards, busways—could soon withstand the decades of weather, traffic, and temperature swings that define the Midlands.

The Role of Surfacing Experts: Why Experience Still Matters

Cutting-edge materials work best with experienced hands behind them. At J.C. Surfacing Ltd, we’re passionate about staying at the forefront of surfacing innovation while delivering traditional quality and attention to detail. Whether you’re looking to resurface a commercial car park, modernise a public highway, or discuss future-proof solutions for your estate, our team is here to help.

Want inspiration? Check out our latest project gallery to see how quality surfacing transforms spaces big and small across the Midlands.

Final Thoughts: Is a Pothole-Free Midlands in Sight?

Self-healing asphalt won’t solve every road problem overnight—but it signals a smart, sustainable future for the Midlands’ transport network. By adopting these materials, cities and towns stand to benefit from longer-lasting roads, safer journeys, and the knowledge that they’re part of the solution to a long-standing infrastructure challenge.

Got questions about new surfacing technologies or how J.C. Surfacing Ltd can help keep your roads, car parks, or business forecourts looking their best? Get in touch with our team for a no-obligation chat—we’re always happy to talk about what’s next for our region’s roads.

JC Surfacing Ltd

JC Surfacing Ltd