Future-Proof Your Surfaces: Innovative Materials and Methods Transforming UK Paving

The world of surfacing and paving in the UK has changed dramatically in the last few years—and it’s only accelerating. As the demands on our infrastructure increase and climate unpredictability grows, there’s more pressure than ever on contractors, property owners, and developers to create surfaces that are attractive, durable, and truly fit for the future.

At J.C. Surfacing Ltd, we’ve had a front-row seat to this evolution. Read on for a look at the most exciting materials, technologies, and design philosophies transforming UK paving, along with practical insights for property owners looking to invest in long-lasting, future-proof solutions.

Revolutionary Materials: More Than Meets the Eye

Resin-Bound Surfaces

Resin-bound paving has quickly become a top choice for everything from modern driveways to public walkways. What makes it so cutting-edge? It combines aggregates like stone and gravel with a transparent resin, creating a surface that is both visually striking and highly practical.

- Permeability: Rainwater can pass right through, helping to reduce puddles and flooding.

- Durability: Resistant to cracks, weeds, and fading—even under heavy use.

- Versatility: Available in countless colours and finishes to suit any property, from period homes to business parks.

- Low Maintenance: Sweeping and the occasional pressure-wash are typically all that’s needed.

When you’re after a combination of minimal upkeep, visual wow-factor, and eco-friendly benefits, resin-bound really ticks a lot of boxes. Interested in resin for your project? Take a look at our resin-bound driveways portfolio.

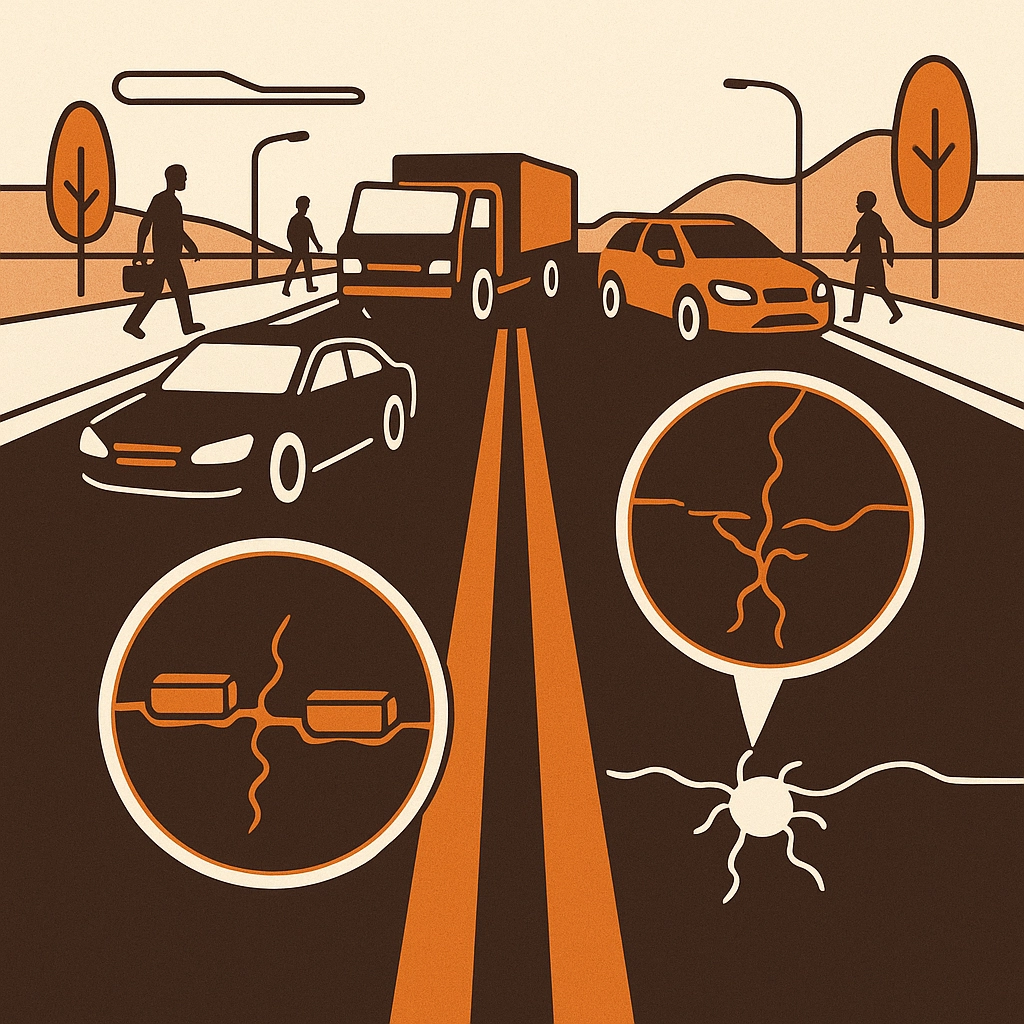

Permeable Paving Systems

Flooding and surface water run-off have become a real headache in many parts of the UK. As towns and cities grow, so too do impervious surfaces—meaning less rain is able to naturally soak into the ground. The solution? Permeable paving.

- How it works: Porous materials like permeable concrete, asphalt, or special paver blocks allow rainwater to filter through the surface and into a substrate below.

- Environmental Impact: By mimicking natural ground infiltration, these systems help replenish groundwater and reduce stress on storm drains.

- Applications: Driveways, parking lots, patios, and even public squares are now benefiting from permeable paving.

Permeable driveways aren’t just “nice to have”—they’re becoming an essential part of water management strategies in new builds and commercial developments.

Grass and Green Paving

There’s also a big move toward blending hardscapes with softer, eco-friendly elements. Grass paving systems, for instance, use concrete or plastic grids that can support vehicle weights but allow grass to grow through, merging the toughness of paving with the look and environmental perks of a living landscape.

- Benefits: Reduce heat, manage rainfall, and add a softer, more natural look to parking areas or access roads.

- Best for: Overflow car parks, fire lanes, event areas, rural properties, and anywhere you’d like “greener” hardstanding without sacrificing strength.

Climate-Adaptive Technology: Surfaces that Work Smarter

Heated Driveways and Smart Melting Systems

Fed up with icy drives in winter? Heated driveway systems are a game changer in the UK, especially as extreme weather events become more common. These systems use embedded electric coils or hydronic tubing beneath the surface to gently warm the paving, melting ice and snow automatically.

- Advantages: Safer access, less manual snow removal, and might just be the best thing ever after a hard frost!

- Considerations: Upfront costs are higher, but the technology’s energy efficiency and damage prevention (no more freeze-thaw cracks!) can pay off over time.

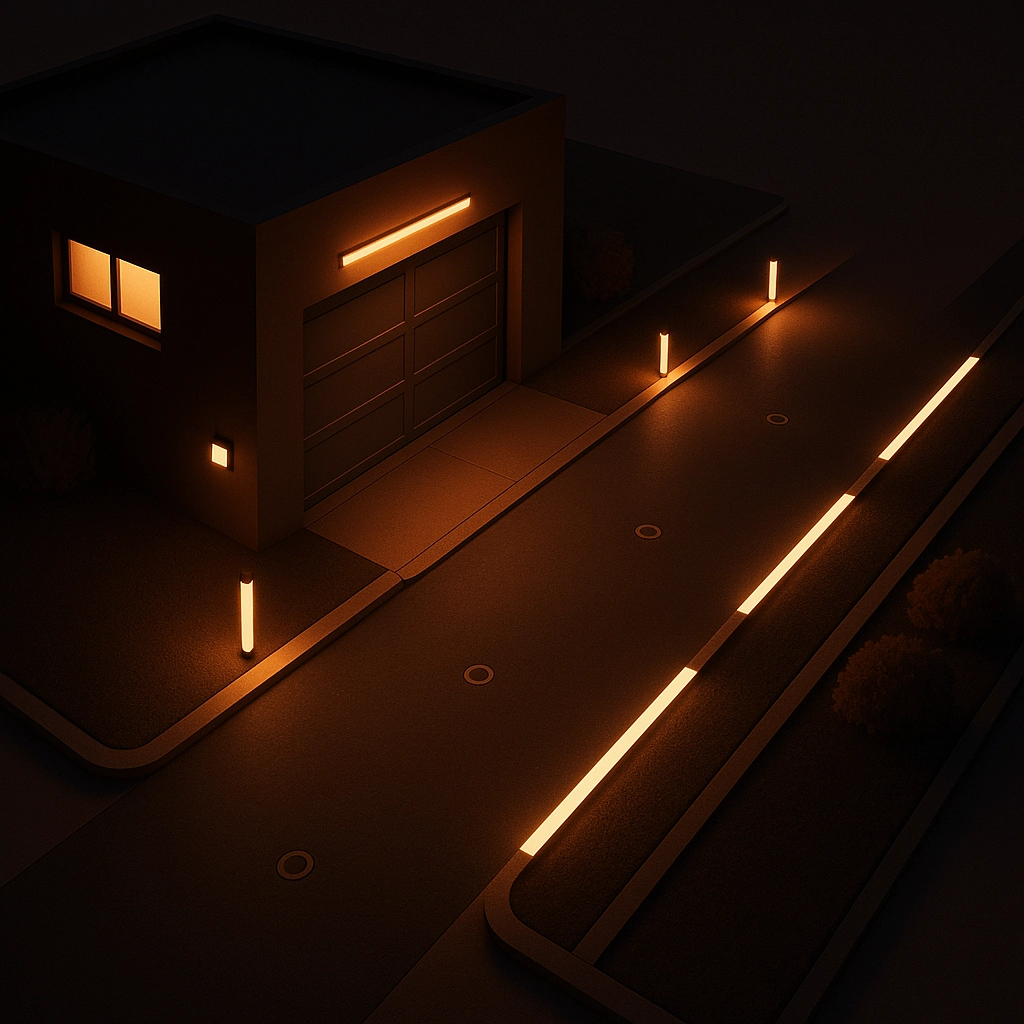

Built-In Sensors, Lighting & Automation

Today’s paving can be surprisingly “smart.” From driveways that use sensors to activate lighting or open gates, to solar-powered walkways that light up only when needed, integrated tech features are becoming mainstream.

- Example Features:

- Motion-activated LED lighting for added security and beauty

- Vehicle detection for automated gate control

- App-connected property access

This technology brings convenience, improved security, and a sleek, modern edge to any domestic or commercial property—and it future-proofs your investment by allowing integration with new systems down the line.

Sustainable Choices: Materials with a Conscience

Recycled & Locally Sourced Products

With sustainability front and centre in construction, the surfacing world is embracing everything from recycled concrete and asphalt to locally quarried stone and even bamboo edging. By repurposing waste materials and reducing transport emissions, these surfaces help shrink your project’s carbon footprint.

- Recycled aggregates: Replace virgin materials with crushed bricks, glass, or tarmac.

- Eco-edges: Use renewable timber or bamboo instead of hard-to-source natural stone.

Sustainable choices are now a key specification point on public tenders and private jobs alike—and there’s no sacrificing strength or appearance to get these green credentials.

Mixed Material Designs

Who says you have to stick to a single style? The latest trend is to thoughtfully combine materials—think concrete with stone borders, resin with gravel insets, or even timber accents within block-paved patios. This “mix and match” attitude brings extra dimension and uniqueness to surfaces.

- Function and Form: Combine durable, easy-clean materials in high-traffic spots with decorative touches where you want style to shine.

- Trend: Grey, anthracite, and off-white tones are dominating, setting the stage for subtle, modern designs with plenty of curb appeal.

Rethinking Design Philosophy

Minimalism and functionality rule the day. Rather than flashy, high-maintenance surfaces, property owners are opting for simple lines, muted palettes, and textures that provide interest without fuss. This not only suits today’s architectural styles, but it helps surfaces “age gracefully” and remain appealing for many years.

Investing in timeless, understated paving delivers value that lasts—something always on our minds at J.C. Surfacing Ltd.

Integration: The New Normal in Surfacing

What’s most exciting isn’t just a single new material or method—it’s the way they’re being combined. On forward-thinking projects, it’s common to see:

- Permeable surfaces with integrated heating for all-season performance.

- Resin-bound driveways with smart lighting and sustainable recycled bases.

- Mixed-material walkways that feature both functional drainage and stunning aesthetics.

This holistic approach means future-proofed paving doesn’t just meet today’s regulations—it goes above and beyond, ready for whatever the next decade has in store.

Looking Ahead: Ready to Invest in Tomorrow?

With all these innovations, the UK paving industry is well and truly on the path toward smarter, greener, and more resilient surfaces. Whether you’re considering a new driveway for your home, a commercial project, or upgrading outdoor space for an academy or sports facility, now is the perfect time to explore these cutting-edge materials and systems.

Curious how future-proof surfacing could transform your property? Explore our commercial services or see recent work in our gallery.

For tailored advice or to discuss your project with our expert team, just get in touch. At J.C. Surfacing Ltd, we’re all about building for today—while planning for the challenges and opportunities of tomorrow.

JC Surfacing Ltd

JC Surfacing Ltd

JC Surfacing Ltd

JC Surfacing Ltd

JC Surfacing Ltd

JC Surfacing Ltd

JC Surfacing Ltd

JC Surfacing Ltd